A coil laser cutting machine allows cutting metal parts straight from coils, with extreme precision and at a higher rate, using less wear. Let’s see how a coil laser cutter works, all its advantages and applications, and the models available.

Discover on this page:

Coil laser cutting is a process that allows you to cut directly from coils and not from metal sheets, saving on costs, time and wear, and making the production much faster and completely automated.

In particular, it has the following advantages:

This process can be applied in different industries, such as automotive and medical sectors. The use of a CO2 laser makes cutting on sheet metal even more precise, without slag production and with an extremely high level of detail.

For this reason, Produtech is specialized in the designing and manufacturing of coil laser cutting machines, that cut metal straight from coil, instead of metal sheets. Our machinery is compact, automatic, flexible, and that guarantees a high productivity rate.

Produtech’s coil fed laser cutting machine is called ISEO and two features differentiate it from the rest of the market:It’s specifically designed to cut metal sheets straight from the coil. A coil-fed laser cutting machine is much more efficient than a regular sheet-fed machine and can provide many advantages.

It’s available in two different series:

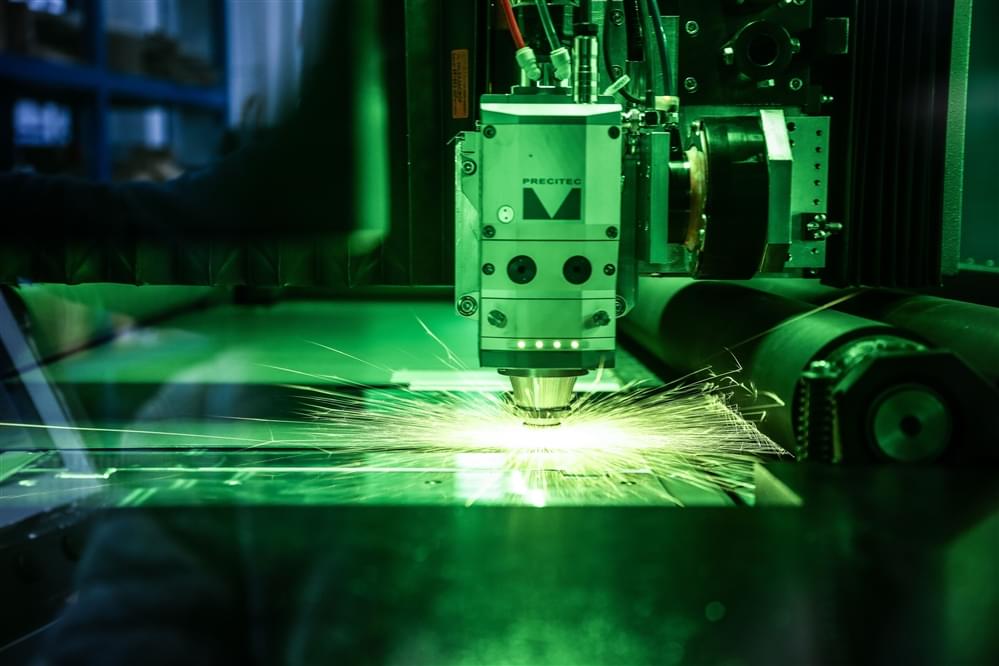

The coil laser cutter ISEO is operated by an optic fiber laser which, compared to the obsolete CO2 laser, guarantees a few advantages: it’s easier to operate and control; it’s much less energy consuming; it needs very little maintenance; it better triggers the cutting activity and runs faster.

The optic fiber technology allows to cut on energy consumption and maintenance costs.

This coil laser cutting machine enhances coil sheet processing by cutting faster than punching machines and with a remarkable productive autonomy, thanks to continuous feeding, reduced maintenance needs and optimized unloading of the cut workparts.

ISEO A1 is the standard version of Produtech’s coil laser cutter series.

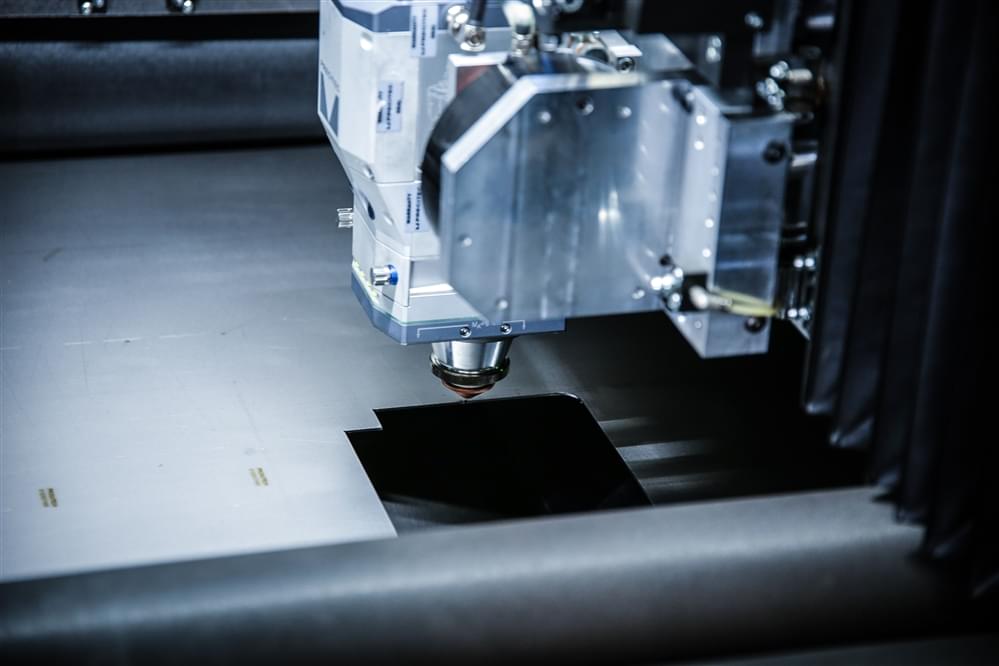

Differently from Produtech’s punching machines, the work area of this coil laser cutting machine is completely closed, according to safety regulations. While on the other hand, the production system works very similarly: the coil sheet advances and its motion is interpolated with the transversal motion of the laser’s axis. Cutting is carried out inside bands with variable length (in general, 500 mm bands): each time, all the necessary cuts are made inside the band, without restart issues, even in case of very long parts.

The fiber-laser source power of this coil laser cutting machine ranges from 0.5 up to 4 kW and it provides extremely precise and well-refined cuts, even on small parts.

The coil fed laser cutter ISEO A2 is the best solution for users who are looking for extreme accuracy, without having to compromise on speed in production rate. This is made possible thanks to the additional Xa axis, which differentiates the two series, A1 and A2.

Produtech punch laser cutting coil-fed EFFICOIL is the ultimate machine for laser cutting. It combines two different technologies: punching and laser. EFFICOIL has two working heads, perfectly synchronized, which operate concurrently but are completely independent. The electric punching unit works on outlines and deformations, while the optic-fiber laser-cutting unit works on internal and external profiles, with obvious benefits:

At this point, we have a complete overview of the advantages of a coil cutting machine compared with a sheet laser machine, which can be summarized as follows:

What is the process for laser cutting? First, let’s see what a laser for industrial applications is. The laser beam is a column of high intensity light of a single wavelength or color. In the case of an optical laser, the one used by Produtech, that wavelength is in the Infra-Red part of the light spectrum.

The beam is only 3/4 inch in diameter. It is created by the laser resonator and travels through the machine's beam path. Before it reaches the plate to be cut, it can be refracted in different directions by a series of mirrors, or beam benders. The laser beam is combined with a compressed gas, such as oxygen or nitrogen, depending on the material being processed. After that, the laser beam is focused by a special lens or curved mirror and pointed to be centered in the machine nozzle. By focusing the laser beam at a single point, the heat density is extreme.

The high power results in rapid heating, melting and partial or complete vaporization of the material, cutting it.

Laser cutting is a precise and efficient method for cutting materials such as metals. The process steps are the following:

The parameters to be set for the laser depend on the features of the machine, the required cutting speed, the material to be cut, and the desired cutting edge.

The laser cutting process and cutting quality depend on the correct selection of laser and workpiece parameters. Deficiencies in cutting quality can be related to the slowness of the process and disturbances caused by fluctuations in speed, variation in power and spatial distribution of intensity, and optical integrity. That's why it is important to rely on a partner like Produtech: we provide you with the necessary know-how in laser cutting technology.

Coil fed laser cutting offers several advantages over other cutting methods. High accuracy, precision, low lead times, less waste, lower power consumption, cutting versatility, the ability to handle complex jobs, and the lack of damage to thick materials make laser cutting far superior.

It is used mainly in the following industries:

Are you interested in our coil laser cutting machine ISEO?

We will show you all its incredible advantages.

Contact us!

Ever since 1993, Produtech has been able to perceive the market’s needs and develop an excellent know-how in manufacturing with coil laser technology. In addition to the long experience in the industry, there are many more advantages resulting from choosing Produtech’s coil fed laser cutters.

Thanks to the use of optic-fiber lasers, in fact, Produtech latest-generation coil-fed laser machines can guarantee precise and powerful work for every need. In addition, the machines require very little maintenance and consequently let you save time and cut costs. Last, when it comes to very thin metal parts, the fiber laser sparks the cut in a better way and works faster.

Summarizing, the main advantages of fiber laser compared to the CO2 laser, are:

Optic-fiber laser is easy to handle, precise and powerful; it requires very little maintenance and so it guarantees significant cost and energy savings. Last, when it comes to very thin metal parts, the fiber laser sparks the cut in a better way and works faster.

As every advanced piece of technology, in order for a coil-fed laser cutting system to ensure impeccable performance and reduce downtime, maintenance is key. Regular and proper cleaning of Produtech’s latest solutions is an integral part of a routine that contributes to preserving the efficiency, the durability, and the accuracy of these machines.

Aconsistent maintenance plan including laser head and optics cleaning prevents buildup, leading to a decrease in cutting precision. Additionally, controlling the internal cooling system of the equipment can help protect this technology from overheating, an event which can cause potential damage to the whole coil-fed laser cutting system.

Another important operation that should be performed regularly is lubrication. In fact, this simple process can preserve mechanical parts from wear and tear. Inspections on a monthly basis reduce the risk of laser misalignment and downtime. Also, it is instrumental to maintain the working area clean and free from debris.

By following these simple best practices, you can prolong the life of your coil-fed laser cutting system, guaranteeing high-quality standards while minimizing troubleshooting. Ultimately, with the help of these solutions, it is possible to implement seamless and faster production cycles for a more efficient manufacturing process.

Produtech is one of the best manufacturers and suppliers in the US market. Thanks to its latest laser coil technologies, our company is able to provide fast and precise fed coil laser cutting machines that require very little maintenance and consequently let you save time and cut costs.

We are capable of working with companies located in every part of the United States, meeting the needs of each client thanks to a dedicated team that follows the project from pre-sales to post-sales maintenance.

Are you interested in our coil laser cutting machine ISEO?

We will show you all its incredible advantages.

Contact us!