Efficient, precise, and fully customizable — Produtech designs and manufactures advanced coil processing machinery for cutting, slitting, straightening, and feeding sheet metal directly from coil.

Our systems integrate the most advanced mechanical and electronic technologies to guarantee maximum accuracy, material optimization, and productivity in industrial environments.

Laser cutting

In addition to manufacturing coil sheet metal processing equipment, Produtech designs and develops solutions for processing copper and aluminum rods.

Combined line

Produtech's punch laser combination machines are one of the most flexible, cost and time-saving solutions on the market for punching and cutting sheet metal from coils. In fact, Produtech EffiCOIL holds two different technologies: punching and laser cutting.

Coil processing machinery refers to the equipment used to transform coiled sheet metal into flat sheets, blanks, or narrower strips of specific dimensions.

These systems prepare material for subsequent manufacturing processes — such as stamping, punching, laser cutting, or forming — ensuring optimal flatness, accuracy, and efficient material use.

Produtech coil processing solutions are engineered to handle a wide range of materials, including steel, stainless steel, aluminum, copper, and special alloys, maintaining tight tolerances and consistent quality from coil to finished part.

Produtech designs and manufactures a complete range of coil processing machinery, engineered to transform coiled sheet metal into high-quality finished components.

Each machine is built to deliver efficiency, accuracy, and flexibility, adapting to different materials, production volumes, and design requirements.

Our lineup includes four main types of coil processing machines — all designed and produced in Italy and equipped with advanced automation and control systems.

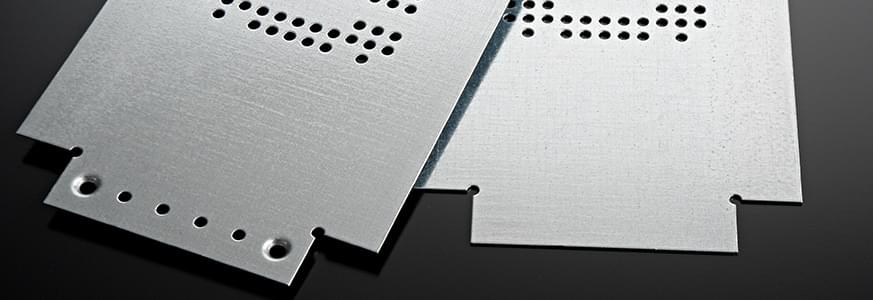

Punching Machines

Produtech’s automatic punching machines represent innovation and high productivity in coil processing.

We offer three lines and seven models of automatic and CNC punching systems, all designed to process sheet metal directly from coil with precision and speed.

These machines guarantee:

Our punching technology is ideal for manufacturers seeking high throughput and reduced material waste, even in multi-shift operations.

Discover our punching machines

Produtech’s laser cutting systems combine cutting-edge optical technology and precise coil handling to ensure the cleanest, fastest, and most efficient metal cutting possible.

Using a focused laser beam, these machines cut through metal coils with minimal material waste and perfect edge quality — even for intricate or complex shapes.

Main benefits:

Explore laser cutting solutions

The EffiCOIL combined line represents the best of both worlds: punching and laser cutting integrated into a single automated system.

This hybrid technology makes Produtech’s combined machines among the most flexible, time-saving, and cost-effective solutions on the market for coil-fed metal processing.

Key advantages:

Ideal for companies that need both high productivity and manufacturing flexibility.

In addition to traditional coil processing equipment, Produtech designs special lines that integrate customized technologies for unique applications.

These include:

Each special line is designed in-house to meet the specific requirements of niche markets — ensuring the same precision, durability, and reliability that define all Produtech machinery.

Produtech’s coil processing machinery is used across multiple industries, including:

|

Feature |

Benefit |

|

High precision cutting and feeding |

Perfect dimensional control and reduced scrap |

|

Material versatility |

Handles steel, stainless, aluminum, copper, alloys |

|

Compact, modular design |

Optimized footprint and easy integration |

|

Full automation |

From coil loading to stacking, with minimal operator intervention |

|

Industry 5.0 ready |

Smart control systems and data connectivity for predictive maintenance |

|

Energy efficiency |

Optimized drive systems and reduced idle consumption |

Unlike traditional sheet-fed systems, Produtech coil-fed lines eliminate intermediate steps and waste.

By processing directly from coil, they offer:

This approach results in a more sustainable, cost-effective, and high-performance production cycle.

With over 25 years of experience, Produtech combines engineering excellence, innovation, and customization in every machine.

Each system is developed in-house, tested, and tailored to meet your exact production requirements — from standard coil lines to fully automated coil-fed punching and laser systems.

Our machines are designed to work continuously, safely, and efficiently, helping manufacturers reduce costs while improving quality and flexibility.

Looking for coil processing machinery designed around your production needs?

Our engineering team will help you configure the most efficient solution — from slitting and CTL lines to fully automated coil-fed systems.

Contact our experts to discuss your project or request a technical consultation.